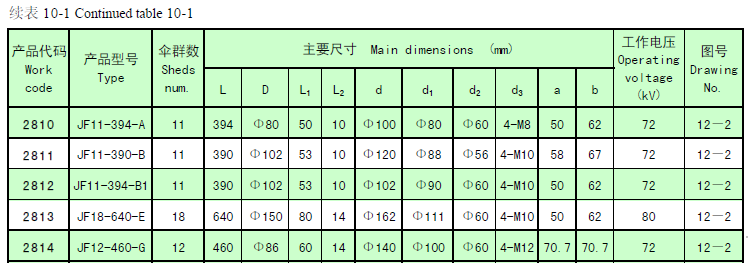

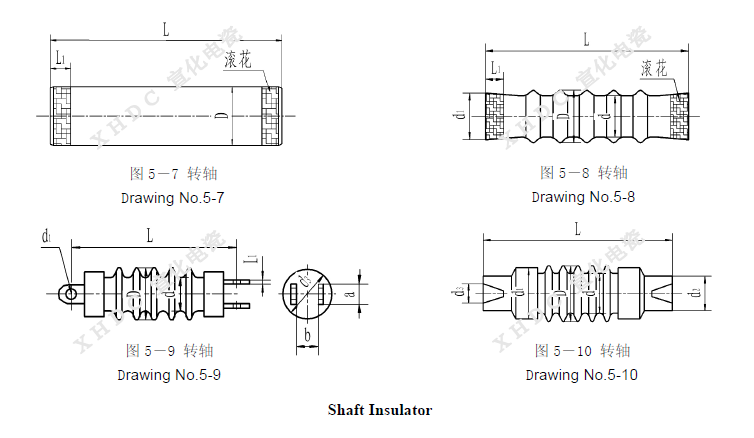

When an ESP is side-rapped for its discharge electrode, a shaft insulator is interposed and connected between the rapping shaft inside the electrical field and the driving gear-motor outside functioning as power transmission for turning the shaft and high voltage insulating between the discharge electrode system and the ESP casing. A shaft insulator consists of the ceramic body and metal fittings at both ends which are cemented together with binder that can withstand high temperature. The cementing faces on a ceramic insulator body are knurling or sanding treated, and a high temperature withstanding elastic layer is interposed between the ceramic body end and metal fittings, and a buffer is also applied between them to prevent from loosening and to ensure mechanical strength.

The insulator is glazed white or brown on the ceramic part surface and the metal fittings are applied with anti-rusting paint.

The ceramic shaft insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

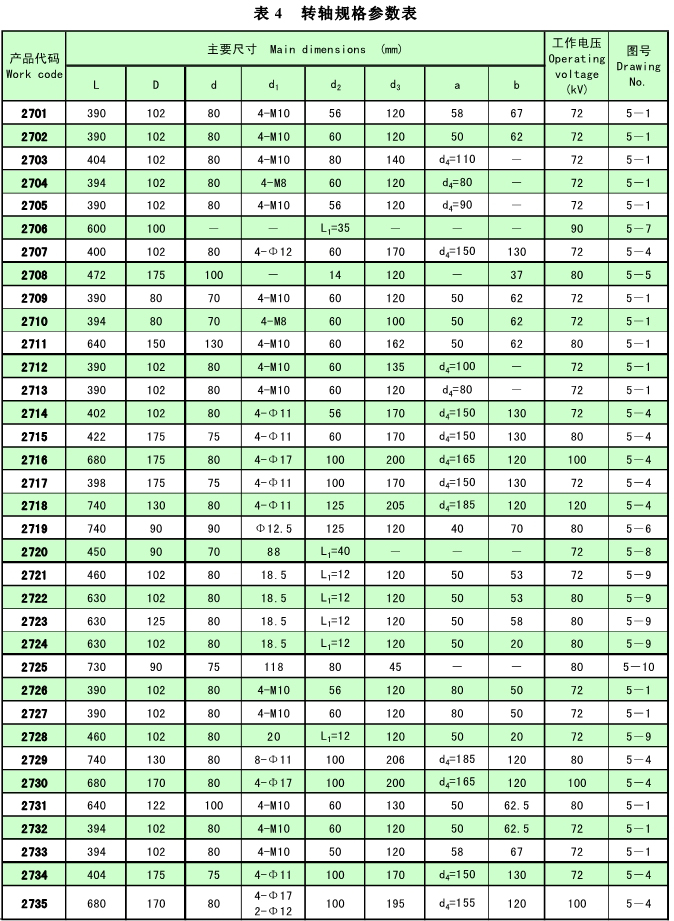

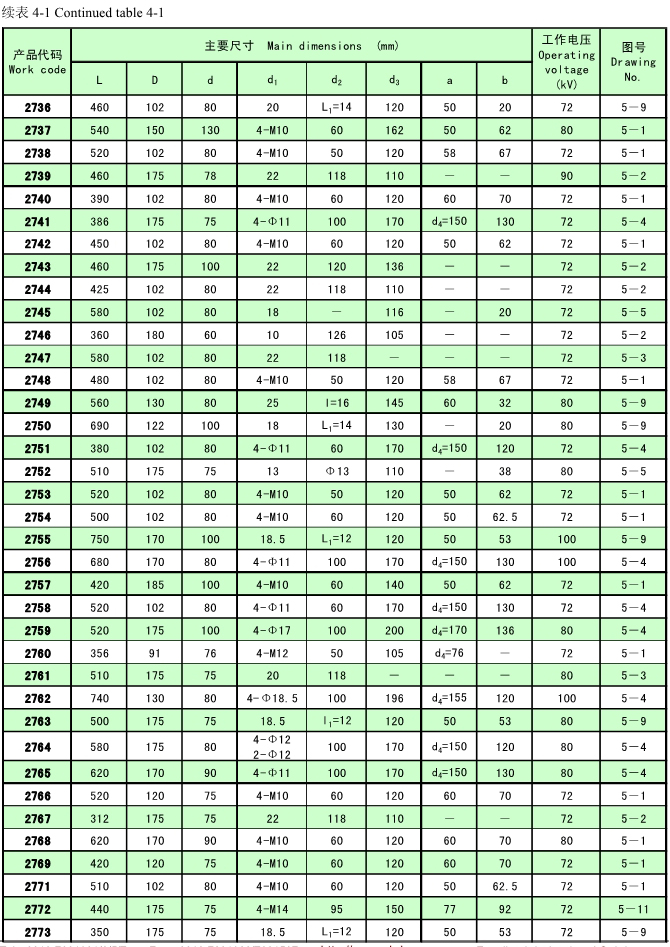

With different materials The ceramic shaft insulator can be used under the temperature ≤250℃ or ≤350℃ with the operating voltage ranging from 72kV to 120kV and a torque failing load not less than 1kN·m.

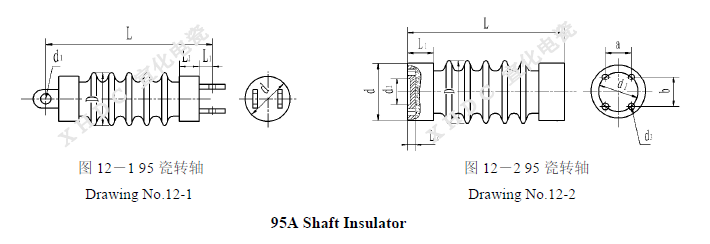

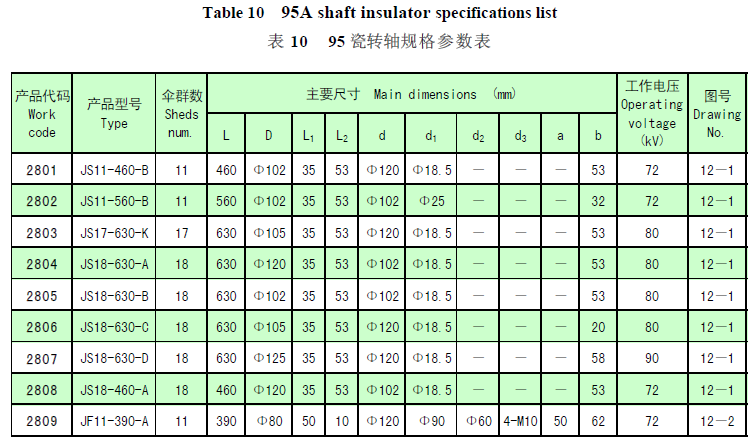

95A shaft insulator is used in ESP which is side rapped for its discharge electrode.

95A shaft insulator can be used under the temperature ≤600℃ with the operating voltage ranging from 72kV to 120kV and a torque failing load not less than 4kN·m.