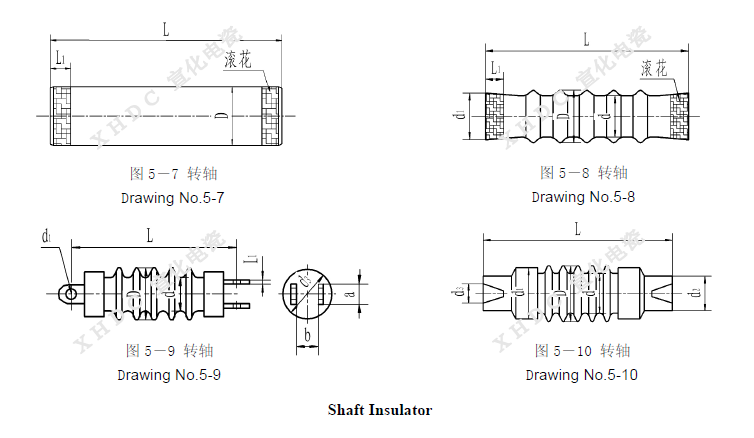

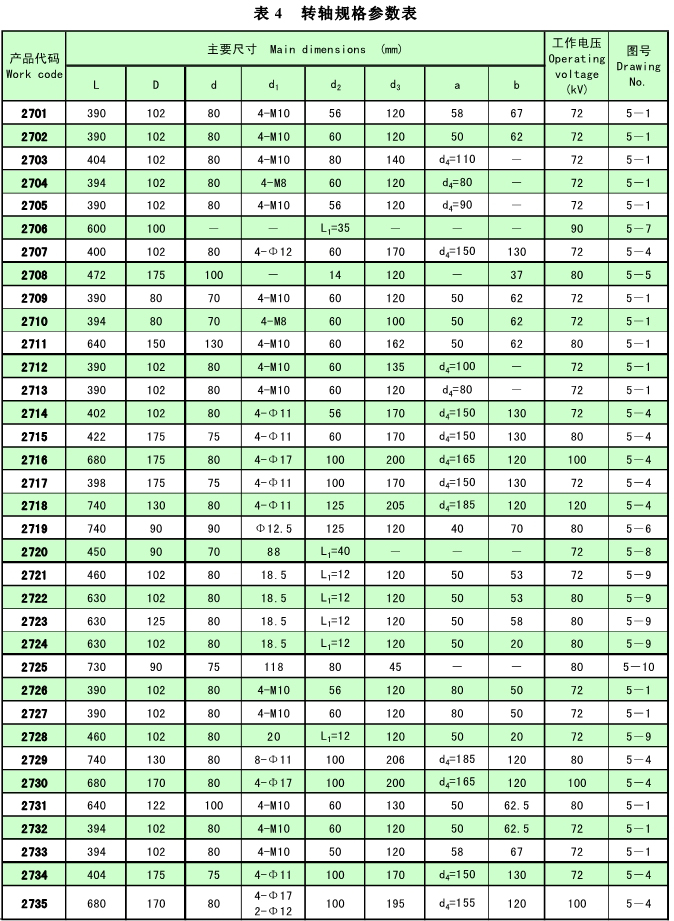

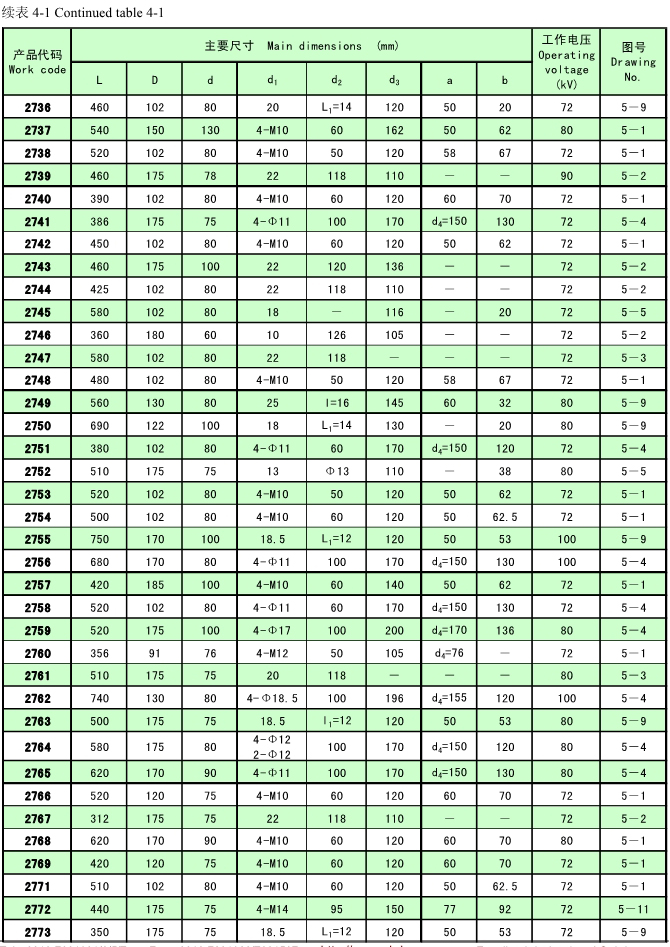

When an ESP is side-rapped for its discharge electrode, a shaft insulator is interposed and connected between the rapping shaft inside the electrical field and the driving gear-motor outside functioning as power transmission for turning the shaft and high voltage insulating between the discharge electrode system and the ESP casing. A shaft insulator consists of the ceramic body and metal fittings at both ends which are cemented together with binder that can withstand high temperature. The cementing faces on a ceramic insulator body are knurling or sanding treated, and a high temperature withstanding elastic layer is interposed between the ceramic body end and metal fittings, and a buffer is also applied between them to prevent from loosening and to ensure mechanical strength.

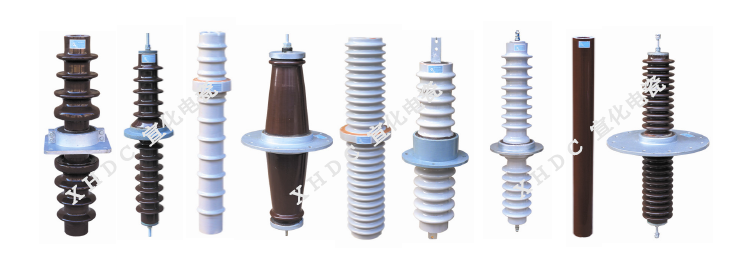

The insulator is glazed white or brown on the ceramic part surface and the metal fittings are applied with anti-rusting paint.

The ceramic shaft insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

With different materials The ceramic shaft insulator can be used under the temperature ≤250℃ or ≤350℃ with the operating voltage ranging from 72kV to 120kV and a torque failing load not less than 1kN·m.

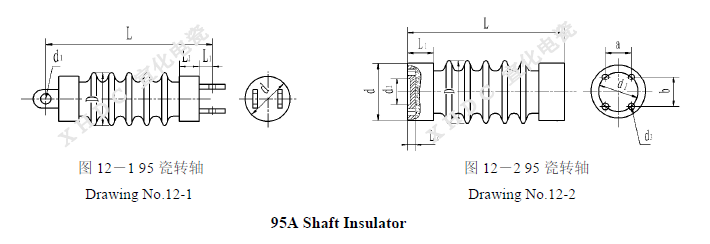

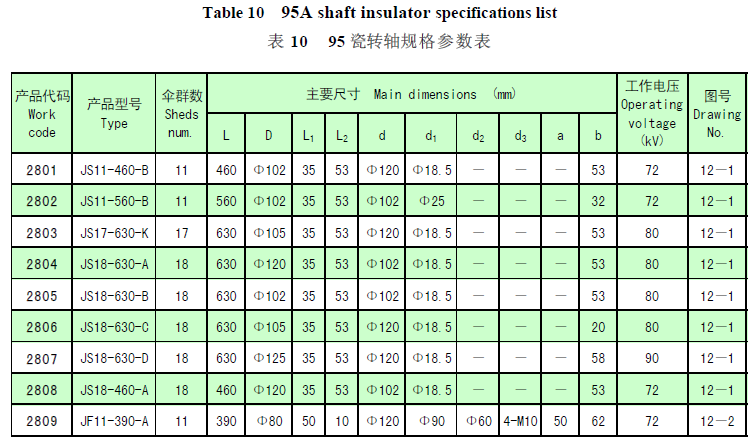

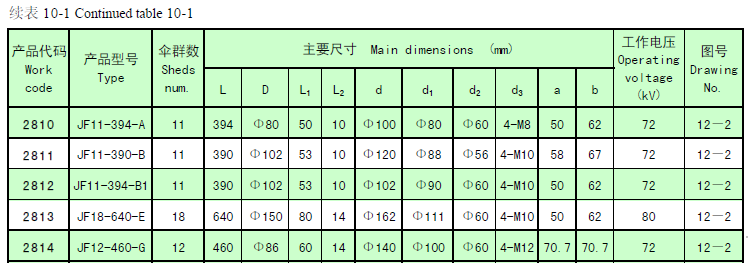

95A shaft insulator is used in ESP which is side rapped for its discharge electrode.

95A shaft insulator can be used under the temperature ≤600℃ with the operating voltage ranging from 72kV to 120kV and a torque failing load not less than 4kN·m.

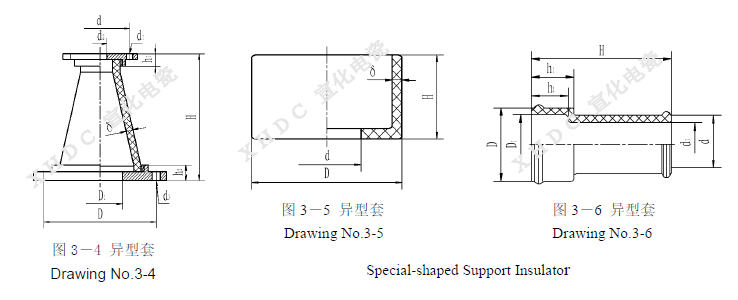

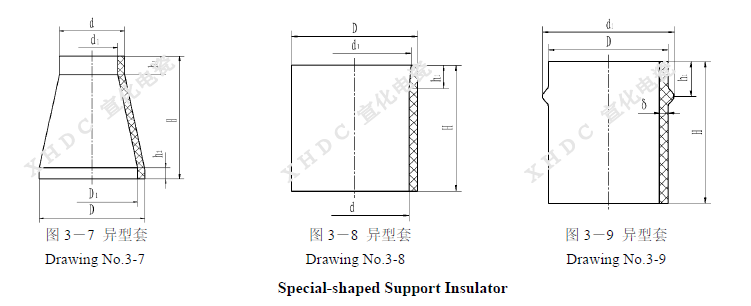

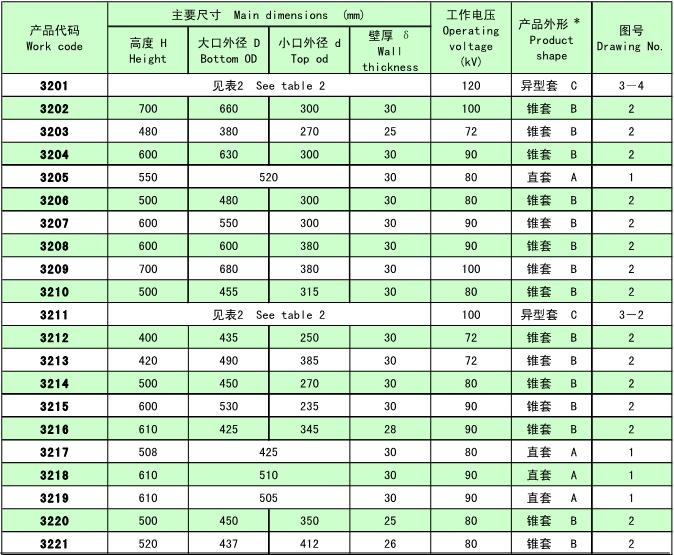

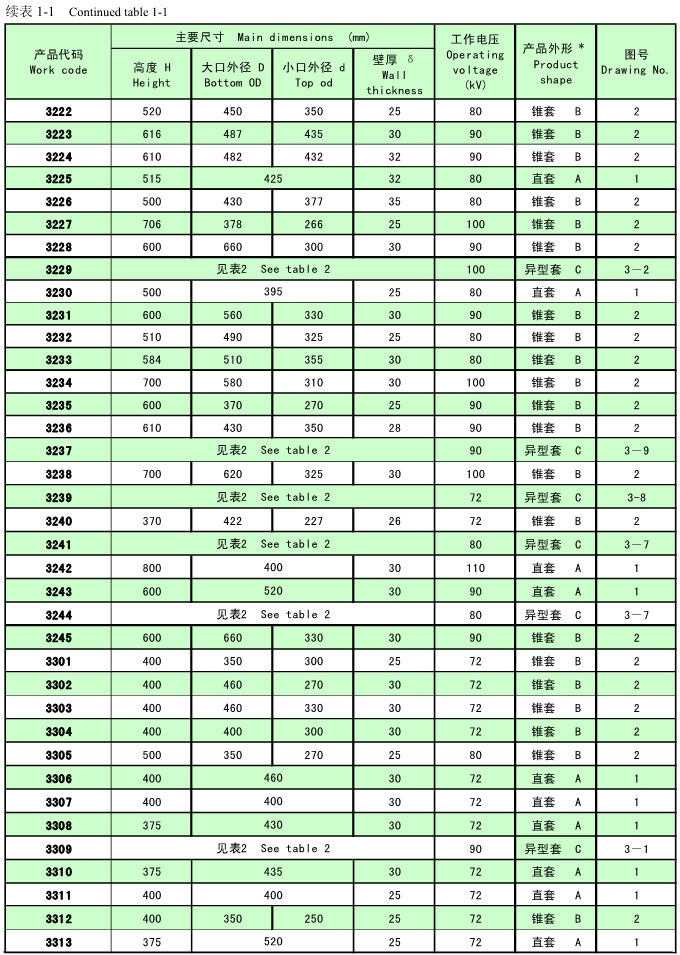

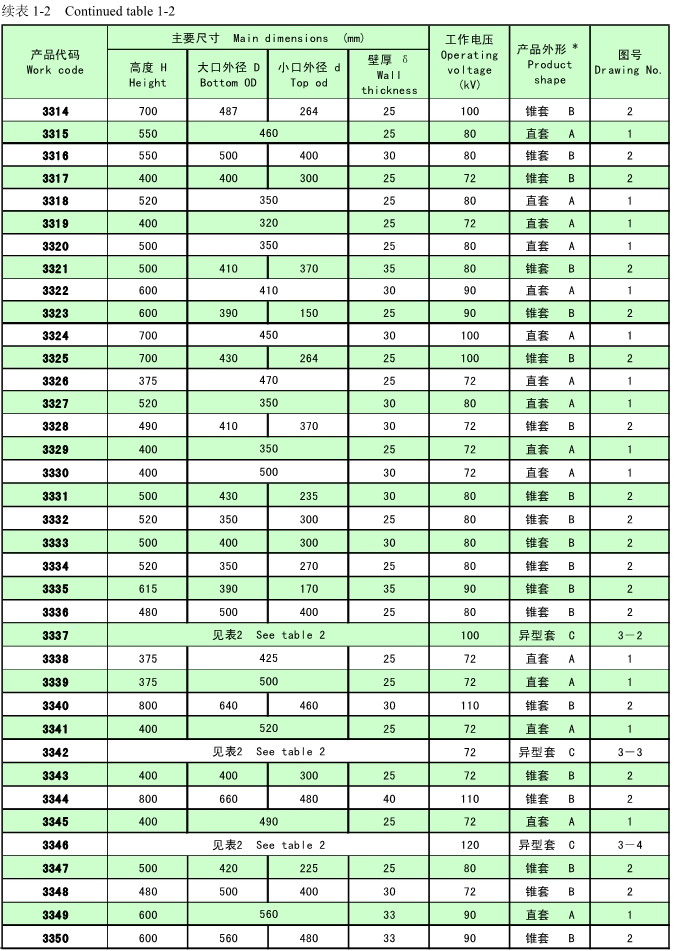

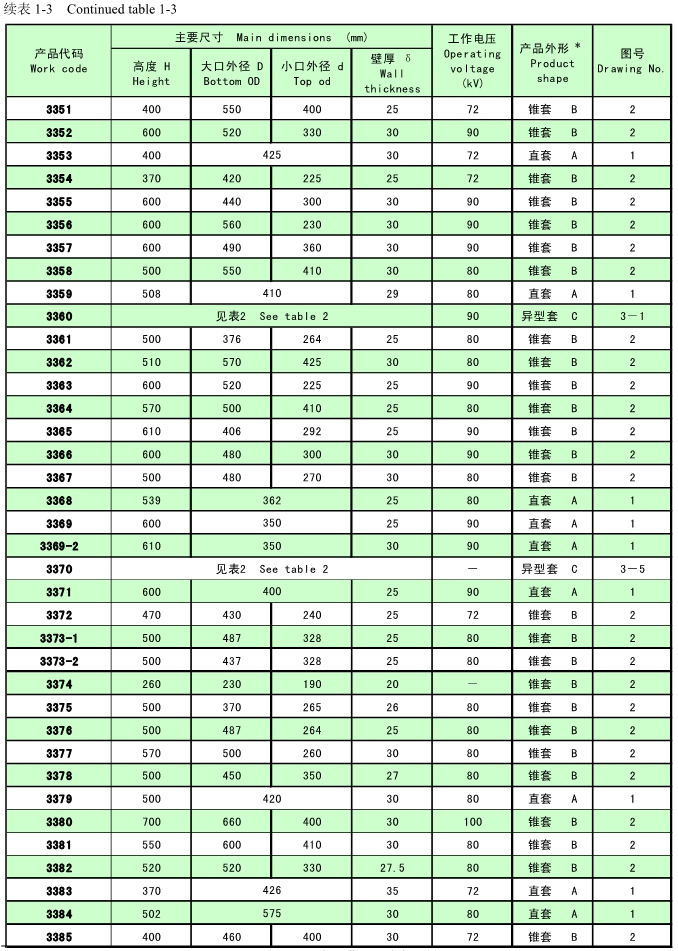

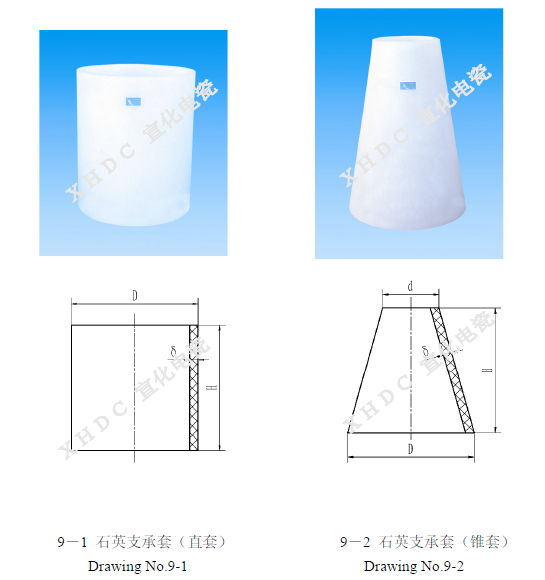

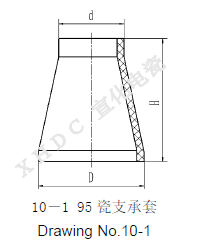

Hollow ceramic support insulator is used as high-voltage insulating and sealing through which the discharge electrode suspension rod entering the electric field in an ESP, and in small size ESP it also functions as supporting of the discharge electrode system. By its configuration, it is classified into three types: cylindrical insulator, conical insulator and special-shaped insulator.

The hollow ceramic support insulator is glazed white or brown on surfaces inside and outside with both ends ground.

The ceramic support insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

With different materials the ceramic support insulator can be used under the temperature ≤250℃ or ≤350℃ with the operating voltage ranging from 72kV to 120kV and a mechanical compressive failing load not less than 500kN.

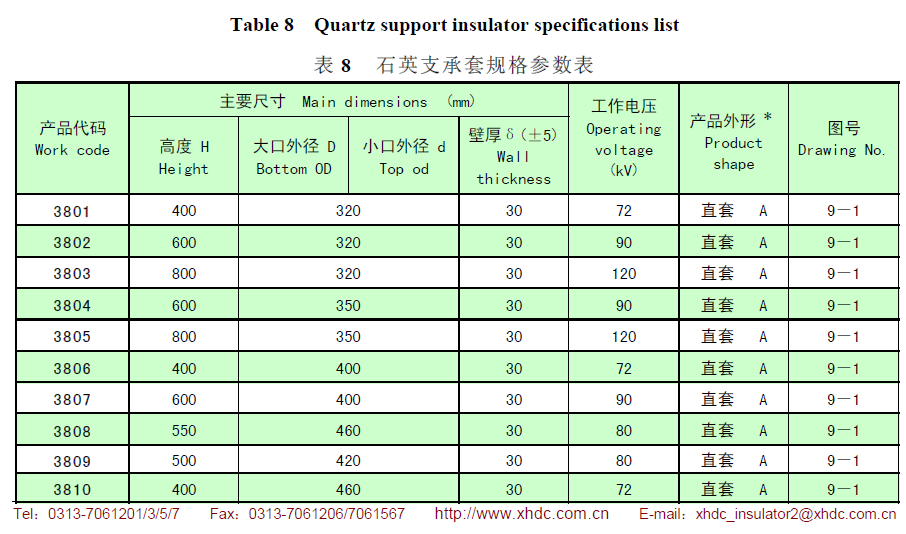

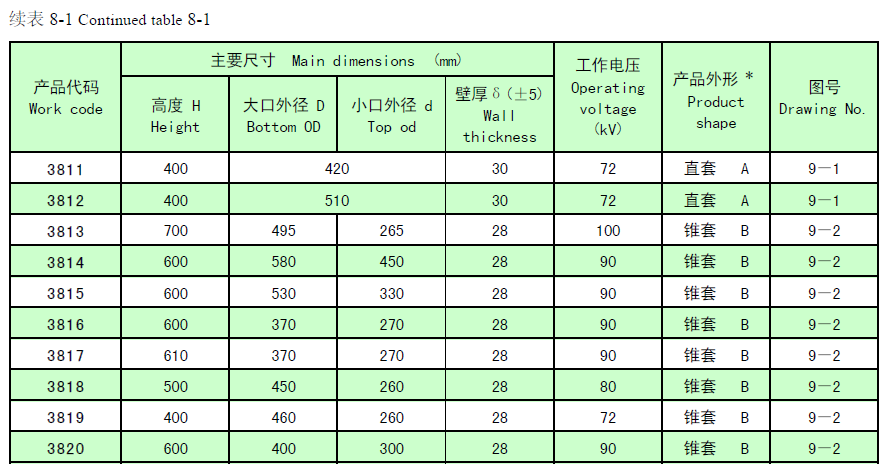

The quartz hollow support insulator is high-purity natural silica based, fabricated through the process of iron-removing, impurities-removing, selecting, pickling and then high–temperature melting, shaping and cooling into non-transparent quartz products with various sizes. It is used in ESP and electric tar remover which are widely used in coal fired power stations, iron and steel plants, cement plants, non-ferrous smelterys, chemical factories and paper making plants.

The specific gravity of opaque quartz glass: 2.06~2.18g/cm3.

Mohs hardness is 5~6

Compressive loading strength: 410~420MPa

Flexural strength: 40~60MPa

Tensile strength: 35MPa

Impacting strength: 0.085MPa

The quartz support insulator can be used under the temperature ≤500℃ with the operating voltage ranging from 72kV to 120kV and a mechanical compressive failing load not less than 300kN.

95A hollow support insulator is used to support the discharge electrode in an ESP, featuring such properties as high-temperature withstanding, high insulating and high mechanical strength, which the ordinary insulators hardly possess.

The 95A support insulator can be used under the temperature up to 600℃ with the operating voltage ranging from 72kV to 120kV and a mechanical compressive failing load not less than 1000kN.

Size: Height≤700mm

OD≤600mm

Wall thickness

δ=30mm

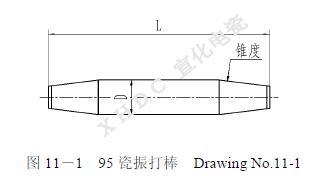

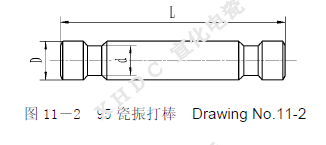

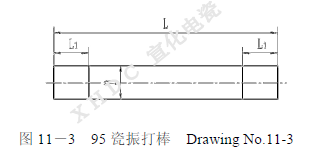

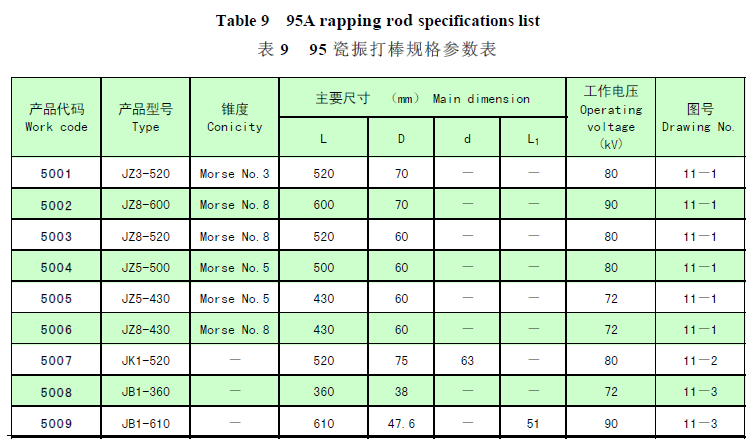

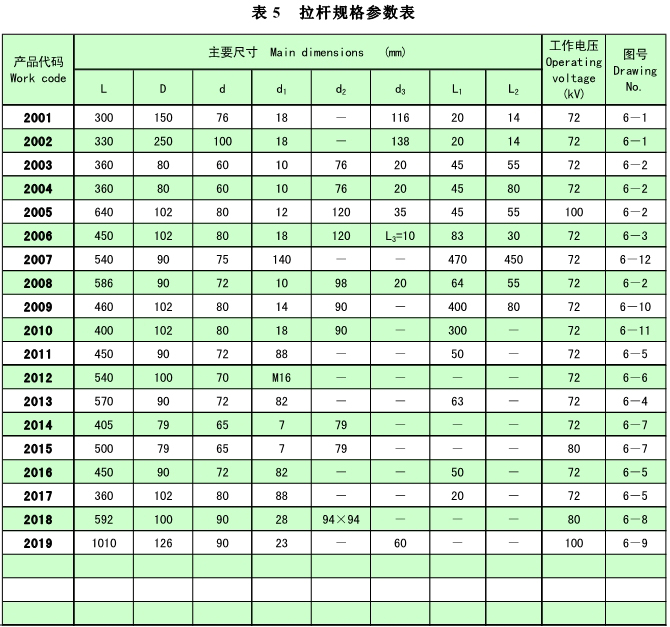

95A rapping rod applies to ESP which is top electrical-magnetic hammer rapped for its discharge electrode.

The 95A rapping rod can be used under the temperature ≤600℃ with the operating voltage ranging from 72kV to 120kV.

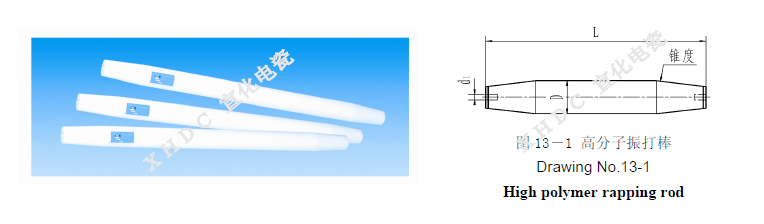

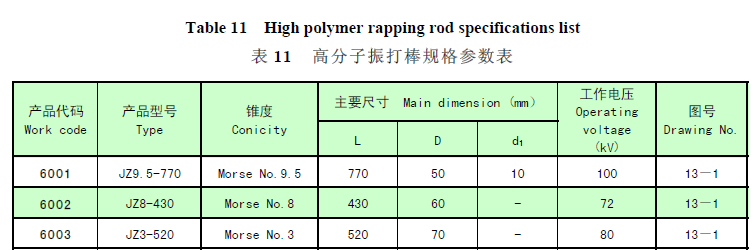

High polymer rapping rod applies to ESP which is top electrical-magnetic hammer rapped for its discharge electrode. It may be used to replace 95A rapping rod with the same size when working at temperature below 200℃, featuring stronger strength, lower specific gravity and super insulating.

Its operating temperature ≤200℃.

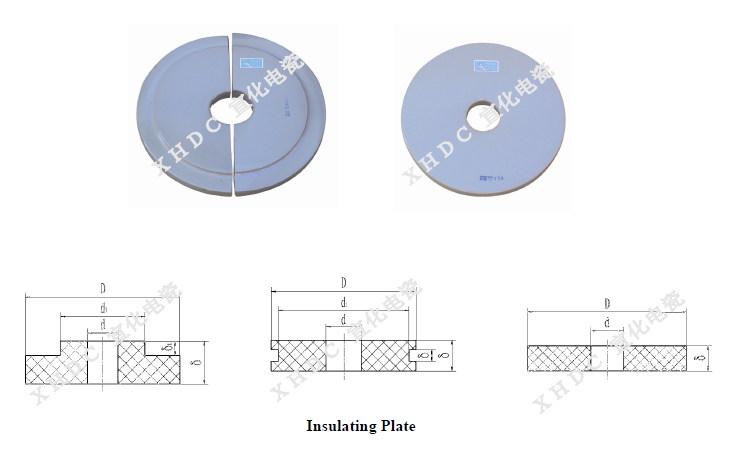

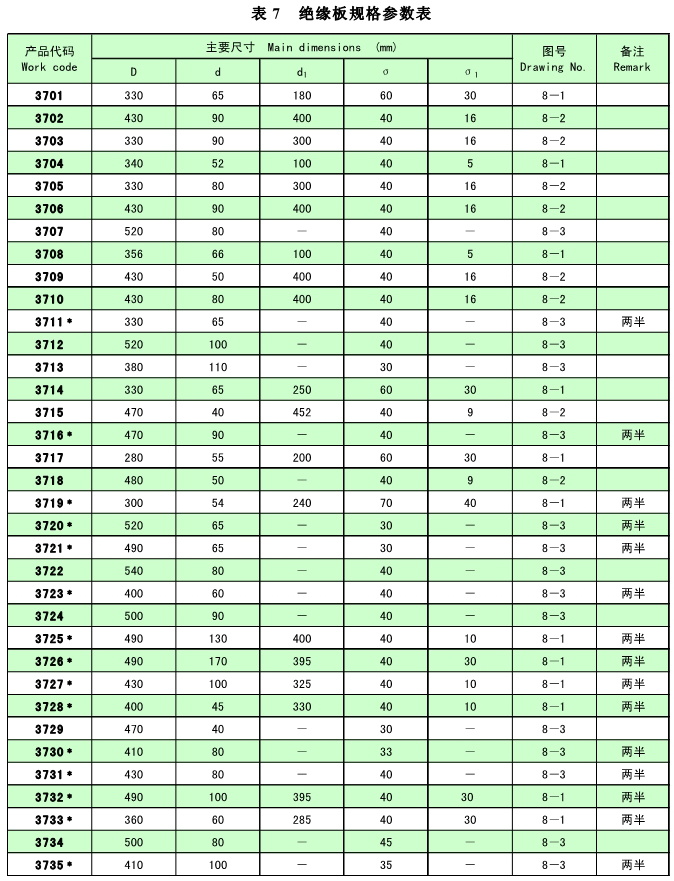

In an ESP, the insulating plate is used together with the hollow support insulator serving as HV insulating, supporting, fixing and sealing. It is classified into the integral ceramic plate and the combined one.

The plate with mark ‘﹡’ means the combined ceramic plate.

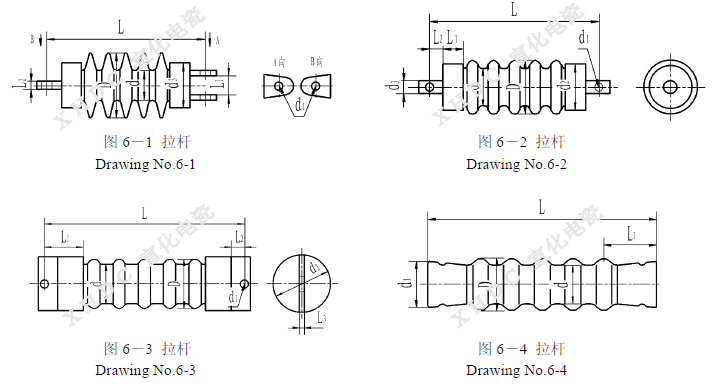

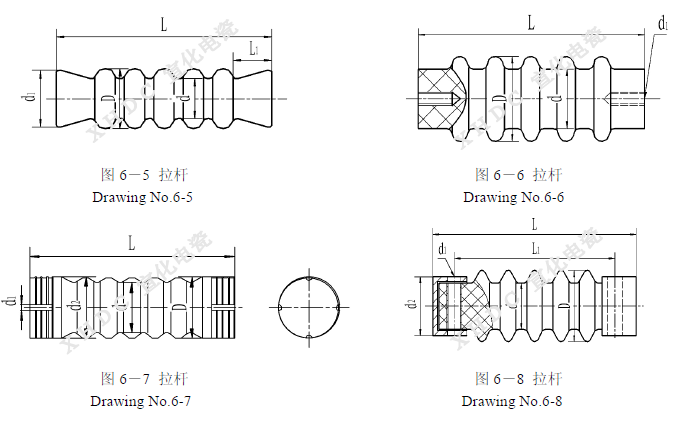

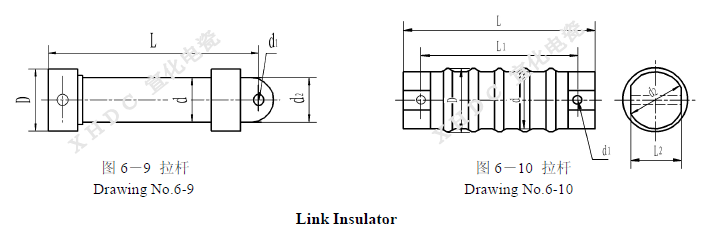

Link insulator is used between the discharge electrode framework and ESP casing functioning as connecting and high-voltage insulating. By its own structure it is divided into two types: pure ceramic insulator and combined insulator.

A combined insulator consists of the ceramic body and metal fittings at both ends which are cemented together with binder that can withstand high temperature. The cementing faces on a ceramic insulator body are knurling or sanding treated, and a high temperature withstanding elastic layer is interposed between the ceramic body end and metal fittings, and a buffer is also applied between them to prevent from loosening and to ensure mechanical strength.

No metal fittings for pure ceramic insulator type. The insulator is glazed white or brown on the ceramic part surface, and the metal fittings are applied with anti-rusting paint for the combined insulator type.

The ceramic link insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

With different materials the ceramic link insulator can be used under the temperature ≤250℃ or ≤350℃ with the operating voltage ranging from 72kV to 120kV and the tensile failing load not less than 15kN.

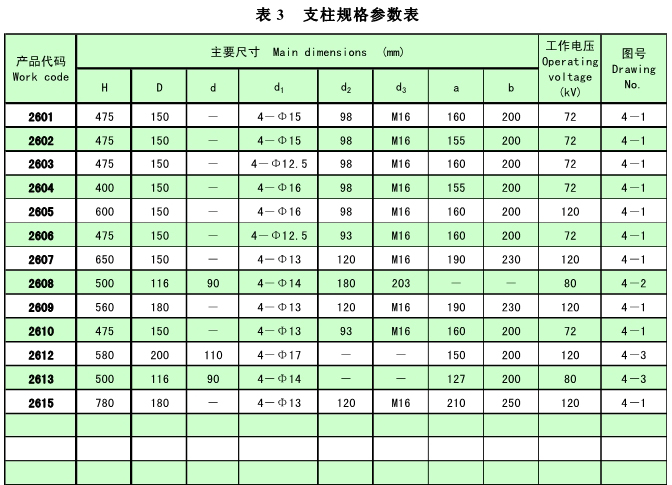

Post insulator is used as high-voltage insulating between discharge electrode system and ESP casing, and meanwhile supporting the weight of the entire discharge electrode system. A post insulator consists of the ceramic body and metal fittings at both ends which are cemented together with binder that can withstand high temperature. The cementing faces on a ceramic insulator body are knurling treated, and a high temperature withstanding elastic layer is interposed between the ceramic body end and metal fittings, and a buffer is also applied between them to prevent from loosening and to ensure mechanical strength.

The insulator is glazed white or brown on the ceramic part surface and the metal fittings are applied with anti-rusting paint.

The ceramic post insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

With different materials the ceramic post insulator can be used under the temperature ≤250℃ or ≤350℃ with the operating voltage ranging from 72kV to 120kV and a mechanical compressive failing load not less than 300kN.

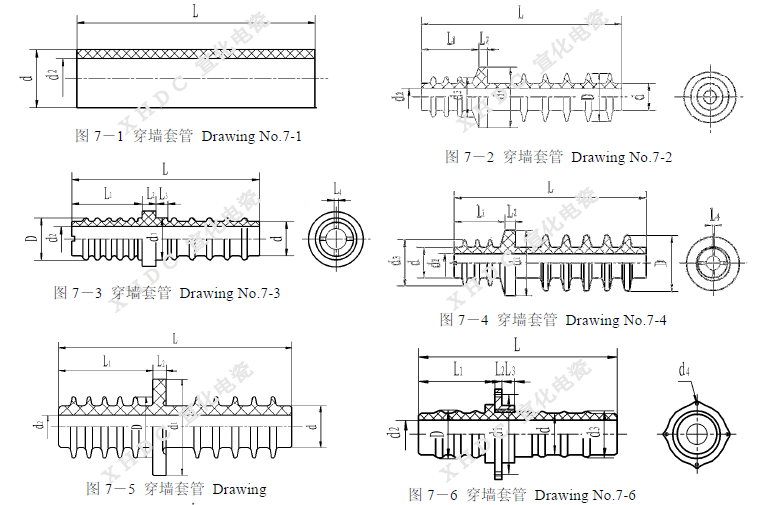

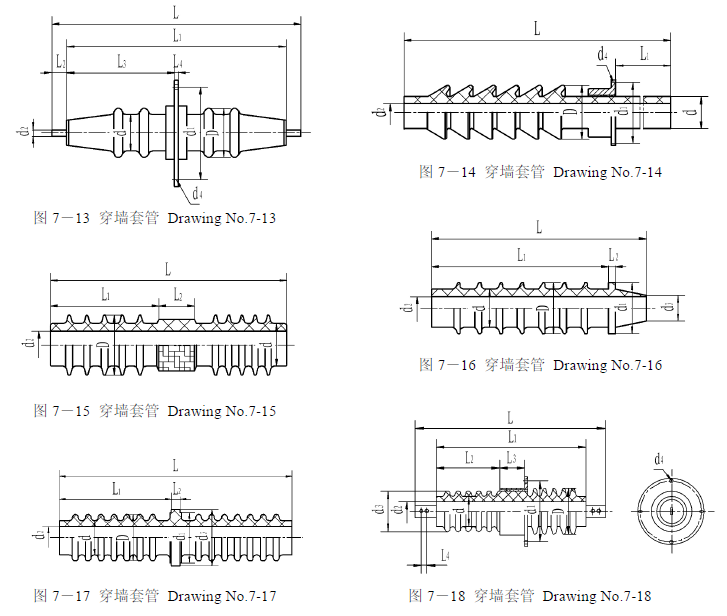

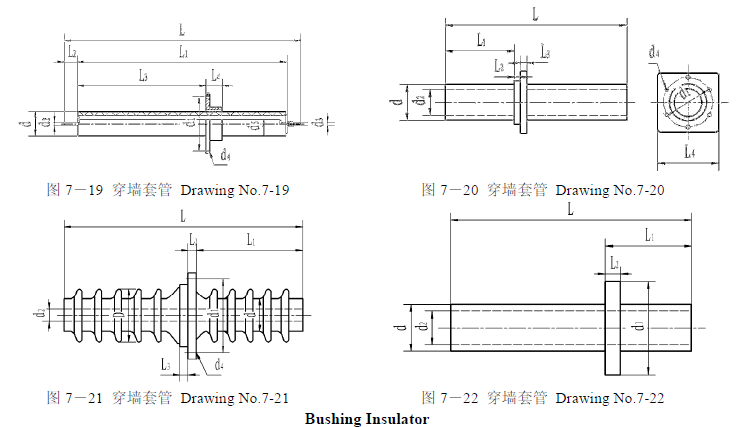

Bushing insulator is used between the transformer rectifier and the discharge electrode suspension of an ESP for leading high voltage into the electric filed, functioning as insulating and supporting of the bus rod. By its own structure it is divided into two types: pure ceramic insulator and combined insulator.

A combined insulator consists of the ceramic body and metal fittings which are cemented together with binder that can withstand high temperature. The cementing faces on a ceramic insulator body are knurling or sanding treated, and a high temperature withstanding elastic layer is interposed between the ceramic body end and metal fittings, and a buffer is also applied between them to prevent from loosening.

No metal fittings for pure ceramic insulator type.

The insulator is glazed white or brown on the ceramic part surface, and the metal fittings are applied with anti-rusting paint for the combined insulator type.

The ceramic bushing insulator conforms to the Chinese standards of GB/T772-2005 ‘Technical specifications for high-voltage insulator’ and JB/T 5909-2010 ‘The ceramic insulator used in precipitator’, and the IEC series standard is also followed.

It’s operating voltage ranging from 72kV to 120kV.